Autonomous Automated Box Opening

#1 Commercialized Box Opening Automation Technology Worldwide

1,500

Boxes Opened in One Hour

1,000,000,000

Boxes Manufactured Each Year in US

Autonomous Automated Box Opening

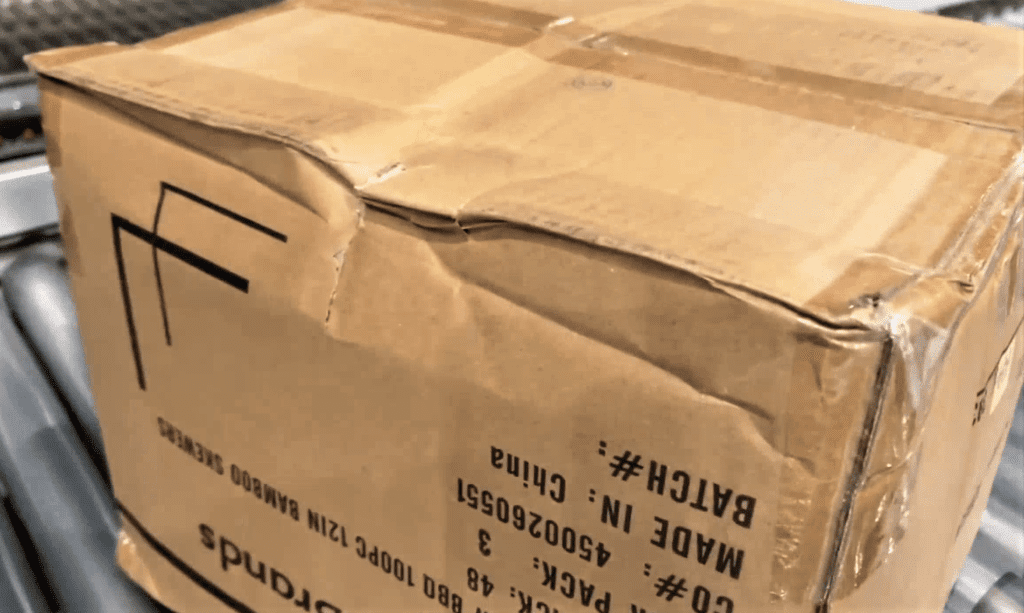

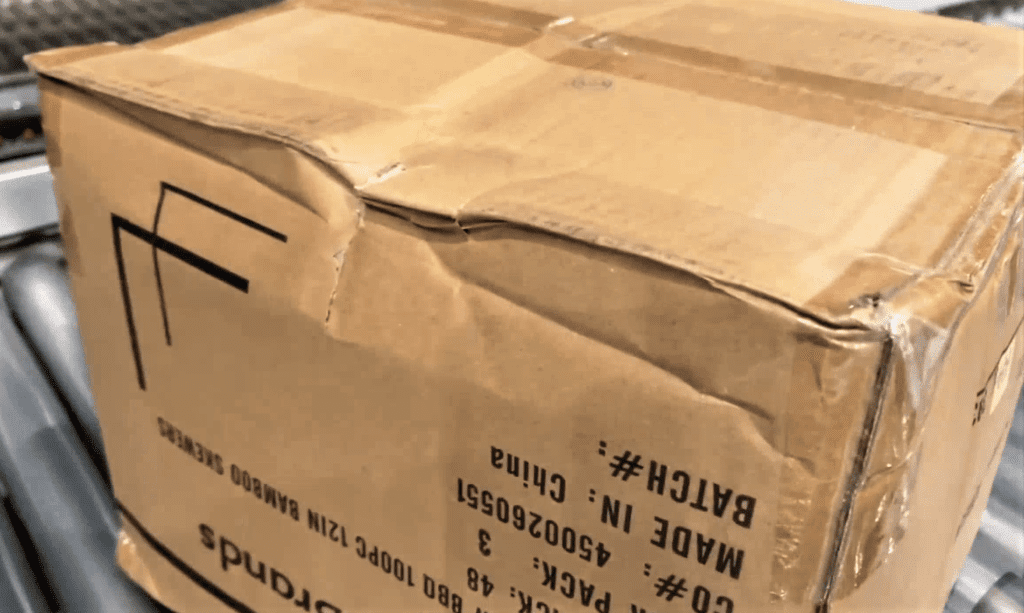

ABOT® will precisely cut a box of unknown size, contours, wall thickness, and condition without damage to the contents or need of human assistance.

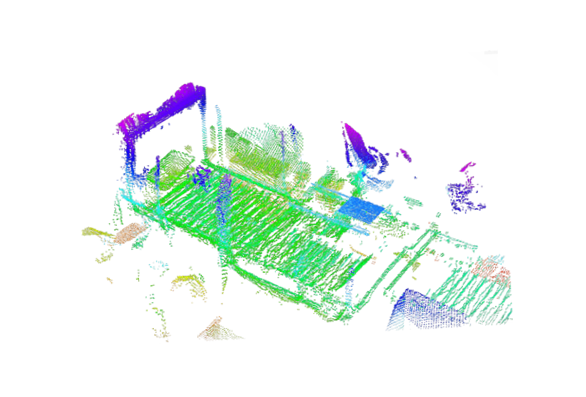

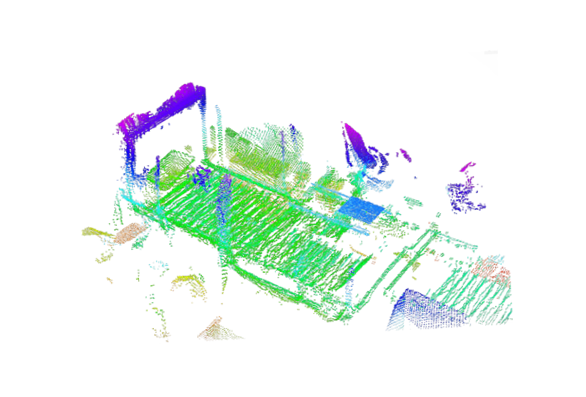

MOST ADVANCED LiDAR IN USE.

EXCLUSIVE ROBOTICA TECHNOLOGY:

At 1000 times per hour, Robotica Systems will determine a six-dimensional blade path to within 0.04” in a space encompassing 17,280 cubic inches and guide the blade along a compound 3D line at speeds of five feet per second.

Expanded Box Size Range (Largest In The Industry)

Minimum 6”L x 4”W x 2”H

Maximum 30”L x 24”W x 24”H

Oversized Option – 40”L x 26”W x 26”H

ABOT® determines the good, the bad and the ugly. Handles the good, attempts fixing the bad, and sends the ugly for help.

Retail packaging is notoriously diverse and in all imaginable conditions. Robotica systems handle real world conditions autonomously maintaining high uptimes and requiring far less human intervention. Processing techniques for individual SKUs are learned improved and recorded across all systems in the network.

Improved Top Removal

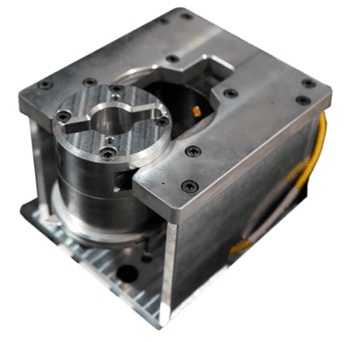

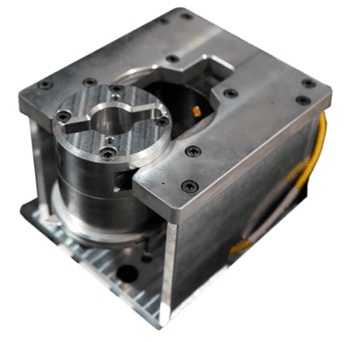

ACE (Automatic Case Extraction)

Patent-pending tool grips box tops and case shells with high forces and without negative pressure inside the case.

Automatically handles a range of box sizes and will remove tops with incomplete cuts.

US & INTERNATIONAL PATENTS

Standard Automated Blade Changing

Tracks blade wear and changes to fresh blades automatically.

Days of uninterrupted operation.

Option for endless blade supply automatically tracking usage and shipping new quantities as needs arise.

US & INTERNATIONAL PATENTS

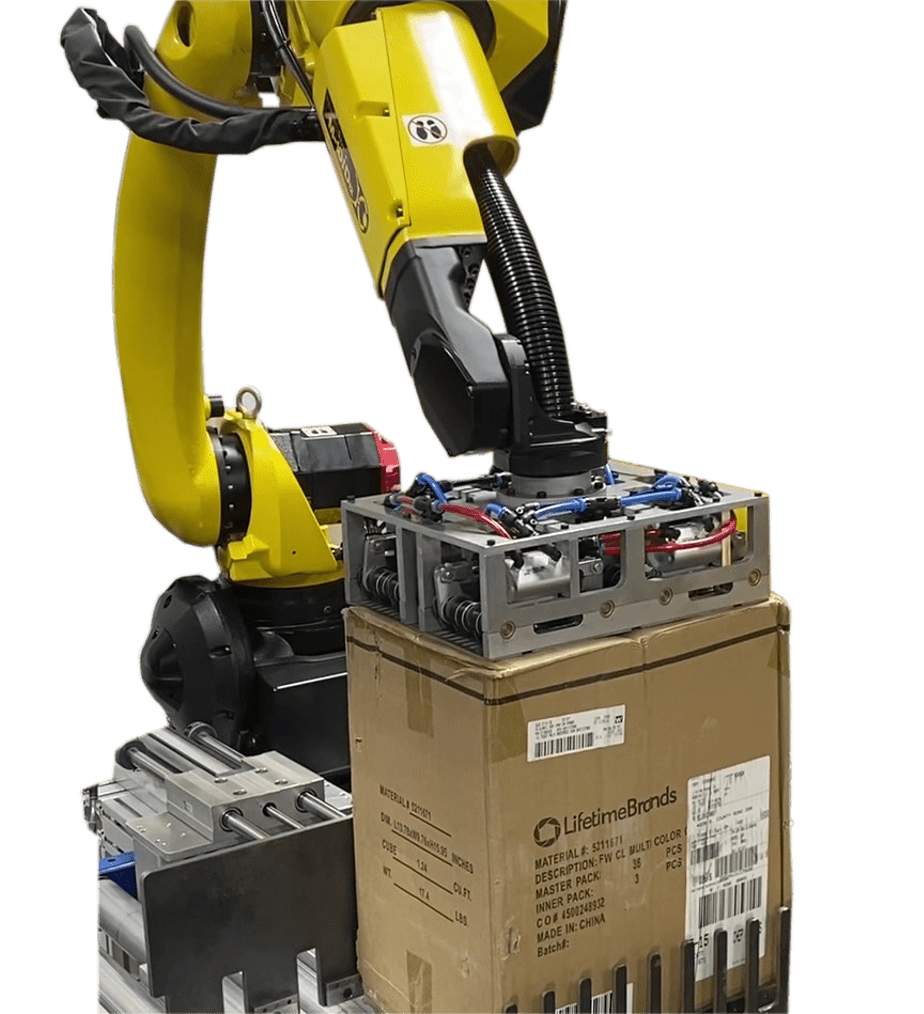

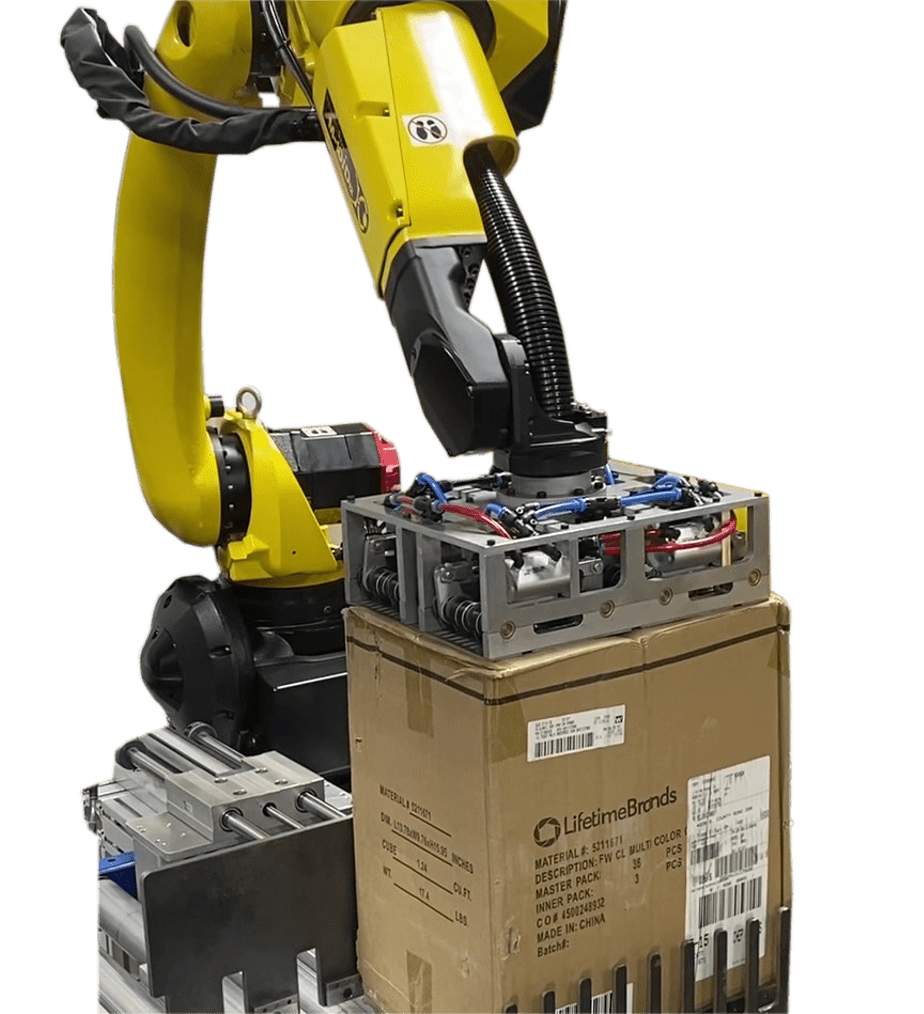

New generation ABOT M1 models are equipped with multiple 3D metrologies and state-of-the art smart robotics. Autonomous operation is aided by remote monitoring and training. High precision three dimensional cut paths and programmable servo box holding tools open an expanded range of box sizes and conditions without damaging contents.

Years In The Making

Cutting open a boxes remains largely a manual operation across industries. Corrugate boxes is the primary storage and shipping medium around the world with 350 billion produced every year.

ABOT is an acronym for Automated Box Opening Technology. Original ABOT technology produced hundreds of successful installations for opening random sized boxes.

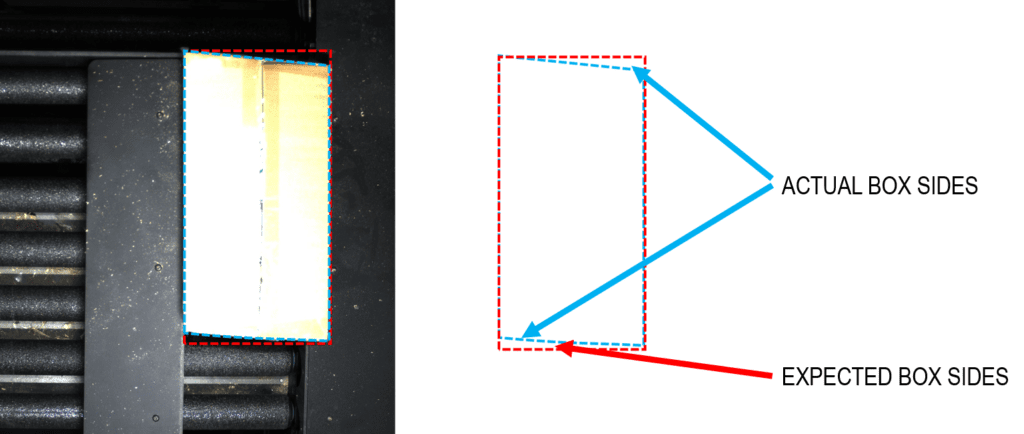

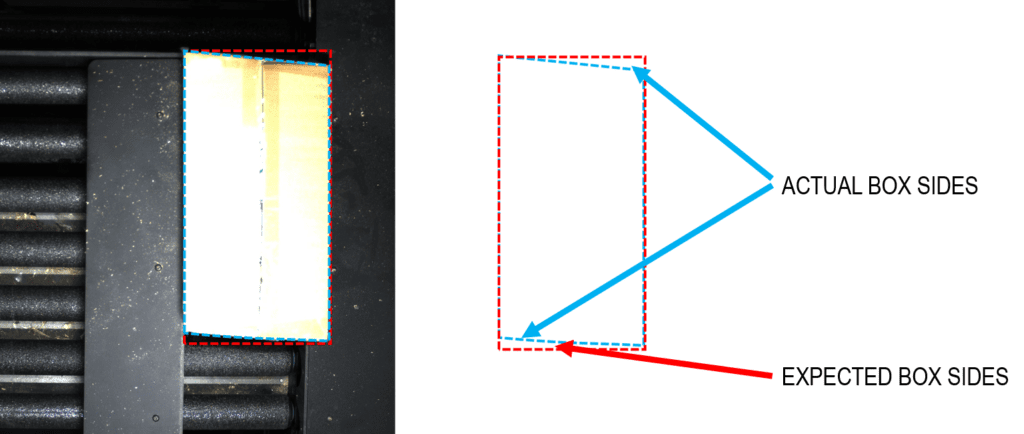

First generation random size box cutters calculate all cuts from single measurements in height, length and width. Cutting on one or more sides is missed when the box is not square or sides are not linear and flat. These machines typically preceded manual decanting for returns or replenishment operations. Workers often complete cutting the robots missed.

Autonomous Box Opening Automation

The new generation ABOT M1 measures tops, corners, and sides with high resolution in 3 dimensions. A cutting path is created in three dimensions. This path is often non-linear and spans a range of vertical and horizontal points matching the actual top of the box.

For the resolution and precision required, measurement data exceeds 16,000,000 points for every box cut. The M1 has the massive processing power to process this data to create the desired robot path reliably thousands of times every day.

Present-day modern warehouse demands for higher levels of autonomy require a new generation of ABOTs. Proven in operations around the world, the M1 series features multiple 3D technologies that evaluate box conditions and opening. Split-second decisions are made handling each and every box. Processing data is stored in a built-in database and shared across installations.

Multiple Intelligent 3D Systems

ABOT evaluates each incoming box. Autonomy requires every in-bound package to be within specifications.

Warehouses do not operate with tight tolerance items like manufacturing. Packaging handled is wide-ranging and constantly changing. Damage and distortions to boxes from shipping are extremely diverse. Even conveying some items can easily be a nightmare. Thus the term is non-conveyable.

It is inevitable out-of-specification boxes will find their way into warehouse automation. Systems not equipped to automatically handle exceptions will incur stoppages, slowdowns, and potential downtime for repairs.

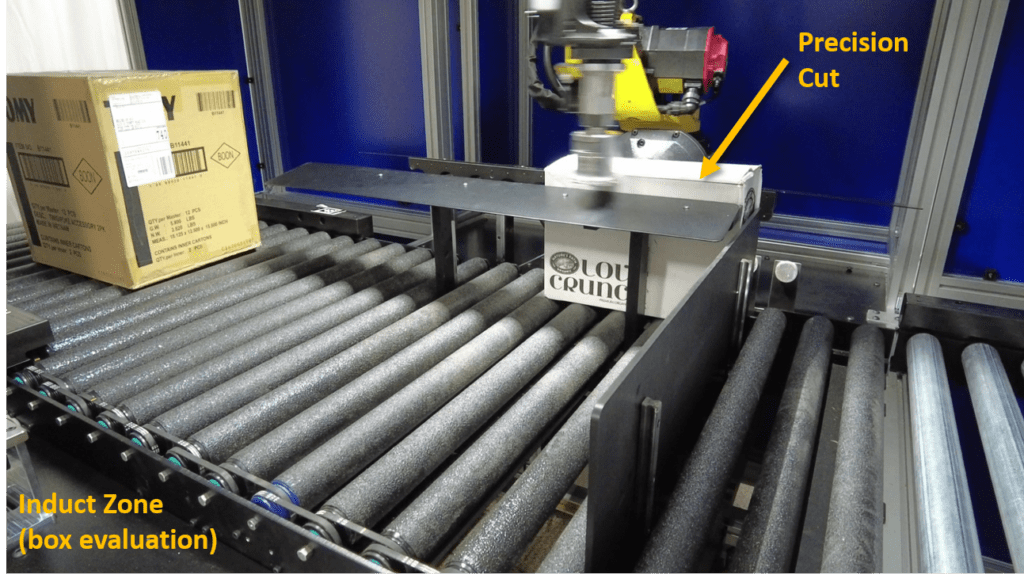

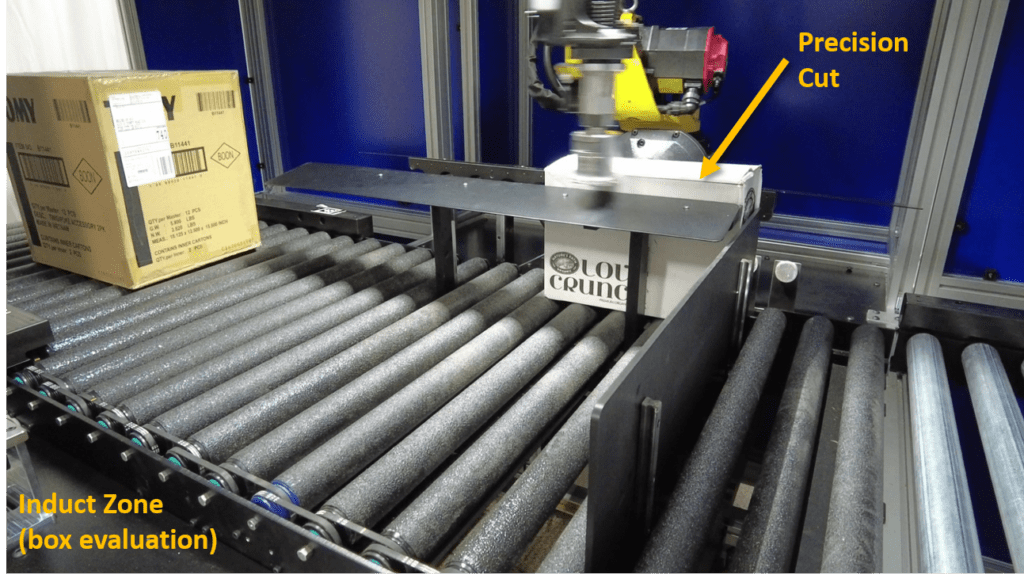

Before boxes are measured for opening, ABOT creates a 3D point cloud on incoming boxes in the induction zone. Boxes are evaluated for severe damage, size, shape, orientation, and position on the conveyor. ABOT will automatically eject boxes it decides it can not process properly.

Servo-controlled Robotic Box Stabilizer

Cutting a box imparts a force to the box. The box must be kept stable held in place and undistorted during the cut.

Structural integrity in boxes is wide ranging. Variety in content and huge variation in corrugate materials require smart stabilization.

ABOT vision controlled robotic box stabilizer adjust for different box heights and widths. Clamping force is variable and controlled based on real time measurements.